Whey Tanks

Tunetanken Whey Tanks are quality tanks made in Denmark, that with their fully moulded design in fiber-reinforced composite material are ideal for storage of whey. Our Whey Tanks are manufactured in composite material which is resistant to degradation, including chemical resistance to aggressive liquids, corrosion resistance, durability against climatic influences and more.

The composite material not only ensures a long life cycle, but also allows for minimal maintenance regardless the stored content and location.

Tunetanken Whey Tanks are always produced to suit specific project requirements, f.e. when it comes to sizing, dimensions, content, connections, appearance etc. – this way we ensure that our Whey Tanks fit to your particular environment providing a storage solution for your exact needs. Therefore, Tunetanken Whey Tanks secure that your investment has the utmost value.

- Size/geometry according to your needs.

- Chemical resistance to aggressive medias.

- Corrosion resistance ensures a long life cycle.

- Insulating construction minimises condensation.

- Smooth surfaces facilitate cleaning.

- No internal seams where the content may accumulate.

- Outdoor installation on a foundation save building costs.

- Simple setup provides a flexible tank which can be relocated.

- Complete solution that provides optimal logistics and operation.

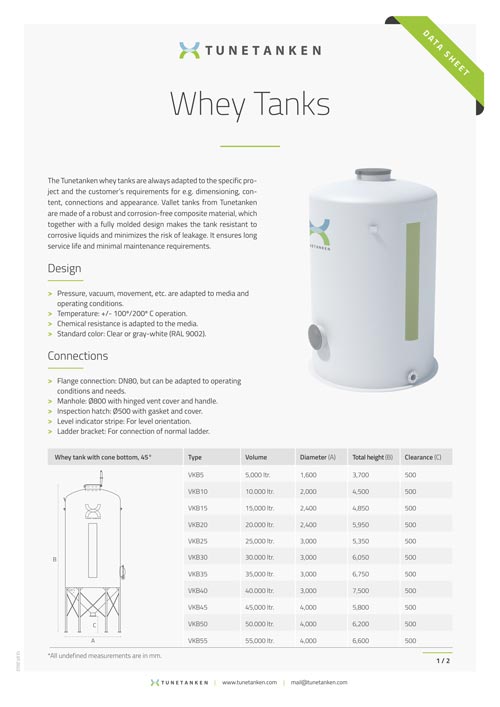

- Load: pressure, vacuum, movement, etc. according to the stored media and operating conditions.

- Density: depends on the stored media.

- Temperature: +/- 100º/200º C at operation.

- Chemical resistance is adapted to the stored media.

- Standard colour: clear or grey-white (RAL 9002).

- Leakage monitoring for hazardous liquids.

- Insulation with PUR-foam and sandwich construction.

- Special colours according to RAL colour card.

- Can be provided with a skirt for protection of bottom outlet and electronic equipment.

- Lining with PP, PVDF or ECTFE for chemical resistance or for storage of food, that requires FCM-approved materials.

- Level indicators and weighing equipment.

- Stirring equipment to hinder precipitation.

- Supply pipe in composite or galvanized, stainless or acid-proof steel.

- Warmth spiral or steam pipe for heating or maintenance of constant temperature.

- Skirt for protection of bottom outlet and electronic equipment.

- Flange studs: DN80 (can be adjusted according to operation conditions and needs).

- Manhole: Ø800 with a hinged ventilation cover and handle.

- Inspection hatch: Ø500 with a gasket and a cover.

- Level indicator stripe: provides continuous overview of the consumption.

- Ladder bracket: for attaching a regular ladder.